What is ARC welding machine Uses - Steps - Hints - warning.

Welding metals with electric arc is the process of joining two pieces of metal using a coated conduction electrode (rod), which melts due to the electric arc and melts from the welded parts.

Content:

- Steps

- Hints

- Warning

- Things you will need

Metals welded with an electric arc are the process of joining two pieces of metal using a coated conduction electrode (rod), which melts due to the electric arc and melts from the welded parts. This article describes the use of in-flow electrodes coated with a typical transformer type welding machine.

What is ARC welding machine Uses - Steps - Hints - warning.

- Steps

Steps include welding with electric arc. An electric arc is formed on the tip of a welding rod when a small amount of electricity passes through the air and continues until welded through a piece of metal. Here are some of the terms used with their description in this article:

Welding machine or welder. This is a machine that converts 120 to 240 volt alternating current (AC) into a proper current for welding, typically 40 to 70 volts alternating current and direct current (DC) to describe other levels of voltage. Is the term used for It usually consists of a large and heavy transformer, voltage regulation circuit, internal cooling fan and amperage level selector. The term "welder" applies to the person performing the welding. A welder is required to operate the welding machine.

Welding wires are conductors that carry low voltage and high amperage current in the welded part. One electrode holder and the other ground wire.

With terminal clamp and handle or electrode holder. This is the device at the end of the electrode carrying cable that holds the electrode, which holds and manipulates the welder to perform the welding work.

Flour and flour clamp. It is a cable that forms a mass, or completes an electrical circuit, and in particular, a clamp that is attached to a piece that can allow electricity to pass through the metal when welded.

Ampere or amp. This is an electrical term, used to describe the current flow level that is supplied to the electrode.

DC and reverse polarity. This is a different configuration used in arc welding or electrode systems that offer greater ability to weld certain types of hard metals or that do not weld well with alternating current. The welding machine that generates this current has a rectifier circuit or is fed by a generator. It is much more expensive than a normal AC welder.

Electrodes are many specialized welding electrodes used for various alloys and types of metals, such as cast iron, stainless or chromed steel, aluminum, or mild or high carbon steels. A typical electrode consists of a hardening rod coated with a special layer that produces an arc, consumes oxygen, and produces carbon dioxide in the welding area, which allows the metal to oxidize Prevents burning of electric arc in welding process. Here are some common types of electrodes and their uses.

- E6011 electrodes: They are made of mild steel (low carbon) with cellulose fiber coating. The first two numbers in the identification of the electrode are the stereotypical force, which is one thousand square. p is measured in pounds per square inch. Here, the electrode voltage will be 60,000 PSI.

- Electrode E6010: They have reverse polarity and are commonly used to weld steam and water pipes, and are especially suitable for "overhead" welding, because the metal is in a liquid state. Also remains in its position, with a drawing on the surface to connect. And follow the exact direction from the electrode to the work piece.

- Electrodes E60XX for other specific uses :: They are available, but since E6011 they are considered standard for general use, and E6010 is considered the standard of DC reverse polarity welding, and we will cover them in detail in this article. Will not talk

- E7018 Electrodes: They are coated with rods High hydrogen flux, with high tensile strength of 70,000 PSI. They are often used in the construction industry to assemble steel structures, and in other applications such as strong composite materials or welds that require high strength. Note that although these electrodes provide great power, they can be weak Proper cleaning of parts (rust, paint or galvanized) is not taken into account when performing high quality welds on steel. These electrodes are called high hydrogen low because they try to keep the amount of hydrogen in them low and must be kept in the oven at temperatures between 120 and 150 ° C (250 ºF and 300 ºF). This temperature is above the boiling point of water, which is 100 ° C (212 ° F) above the surface. In this way, moisture is prevented (H2O) air electrode will penetrate the metal

- Nickel, Iron Alloy or Nickel Iron Electrodes: These special electrodes are made for cast iron, soft or flaky, and have maximum adhesion, to allow expansion and contraction of welded iron materials.

- Bars of various metals: These are made of special alloys and give better results when welding is of hard, hardened or alloyed steel.

- Aluminum rods: They have a new technology and they allow to weld aluminum with traditional welding machine, instead of using tube feed antigen gas welding machine such as MIG (metal, non-gas) or T. Use IG (Tugstein, non-gas) type welding machines, often called helium arc, because helium is the gas used to make flames. The official names created by the American Welding Society (AWS) for this type of autogenous welding are: rod, tig and maig, depending on the material that feeds it.

- Electrode Size Electrodes come in different sizes and are measured by the diameter of the central metal of each rod. There are 0.95 mm (3/8 inch) rods for mild steel electrodes. The exact size depends on the amperage of the machine and the hardness depends on the material to be welded. Each electrode works best in a given amperage range. The choice of the correct amperage range for a given rod-sized lamp will depend on the material to be welded and the desired penetration, so when this welding process is described, specific amperes will be discussed later in this article. Will

- It is important to know how to safely weld safety equipment, keep the right equipment and use it. Here are some basic steps you can take to begin the process of preparation for mediation.

- The masks are worn to protect the eyes and the entire face, neck and head from the glare of the bow, and from the sparks that are emitted during the soldier. Standard welding lenses are very dark colored, as the arc flash can cause burns in the retina of the eye. The minimum darkness level for welding lenses is 10. Masks with "life table" lenses are preferable, as the black lens is designed to leave a clear lens at the bottom and work on metal protected from chips or sparks. Can be picked up The most desirable masks are those that have glass that automatically turns black, and are already available in the market. These glasses are very clear when we use them to cut and polish metal. When the lens begins to weld, when it detects the brightness of the arc, the lens automatically darkens to the 10th degree of darkness. The new masks on the market are masks with automatic black variable shadow lenses.

- Welding gloves are specially insulated leather gloves that extend 15 centimeters (6 inches) beyond the wrist, and protect the welder's hands and arms. In addition, if they come in contact with the operator's electrodes, they provide limited protection to avoid accidental power outages.

- The welding apron is made of leather and covers the welder's shoulders and chest. It is used when welding on the head so that the spark does not ignite or burn the fabric.

- Work shoes that are worn by a person should be worn at least 15 cm (6 inches) from the ankles with a type of boot tied to a stick to avoid burning the feet with sparks or red hot. These shoes must have insulated soles that do not melt or burn easily.

What is ARC welding machine Uses - Steps - Hints - warning.

Learn the steps to perform a successful weld.

Welding is more than just covering the joint with metal wire or gluing one piece to another. This process begins by adjusting and properly securing the pieces, or the metal to be welded, to which we are going to join. For thicker pieces, you have to file the bevel and then fill it with solder points and create a solid bonding surface. Here are the [Basic steps] you can take to begin the process of preparation for mediation

This creates a bow. This is the process of creating an electric arc "between" the tip of the electrode and the work piece. If the electrode simply allows the "rods" to go directly into the part with the ground clamp, not enough heat will be generated that the electrode will melt and the metals will not melt.

Move the arc to form a weld point or drop. A "drop" or weld point is a form of metal that occurs when an electrode and a base metal melt together. This fills the space between the pieces that are joining and welded.

Shape the weld. In zig zag or 8 movement, this is done by moving the arc back and forth to be welded, so that the metal is divided in the width of the space between the pieces so that the welding is to your liking.

Polish and weld between one pass and the other. Each time you complete a "pass", or turn from one end of the weld to the other, it is important that you remove the pieces of molten electrode that remain at the weld point level, so that Only very solid metal remained. Before proceeding with the next pass

What is ARC welding machine Uses - Steps - Hints - warning.

Assemble the tools and equipment you need to start welding. These are: welding machine, electrodes, wires with their clamps and welded metal.

What is ARC welding machine Uses - Steps - Hints - warning.

Preferably create a safe place to work with a table made of steel or other non-combustible material. To practice you will be served a few pieces of mild steel, at least 0.95 mm (3/16 inch) thick.

What is ARC welding machine Uses - Steps - Hints - warning.

Prepare the metal to be welded. If the metal consists of two pieces that need to be welded together, you will need to prepare them by filing a bell-shaped edge on either side. This can cause a lot of "penetration" into the soldier's arc which can melt both sides and melt them together so that the welding material fills the joint and welds the pieces, instead of "just sticking them". At the very least you need to remove any paint, grease, rust or other contaminants so that you can work on a very clean surface and perform quality welds.

What is ARC welding machine Uses - Steps - Hints - warning.

Attach the metal pieces with tweezers so that they can be securely fastened if necessary. Pressure clamps "sergeant" or locking tongs usually work well for this. For special projects, you need to find suitable techniques that fit the pieces to make sure they are in the correct position when joining the weld.

What is ARC welding machine Uses - Steps - Hints - warning.

Place the dough clamp on the largest piece you are going to weld. Make sure it is in a clean place so that the electrical circuit is completed with the lowest possible resistance at the ground point. Again, if there is rust or paint, clean it so that it does not interfere with the flow of electricity and the arc occurs more easily when you start welding.

What is ARC welding machine Uses - Steps - Hints - warning.

Choose the right dipstick and amperage range for what you are going to do. For example, a 6, 35 mm (چ inch) steel plate can be welded between a 3.60 cm (1/8 inch) E6011 electrode and 80 and 100 amp. Place the electrode on its electrode holder clamp to ensure that the insulated part of the clamp makes good contact with the area at the beginning of the rod that has no insulator.

What is ARC welding machine Uses - Steps - Hints - warning.

Turn on the welding machine. You should hear a soft sound from the transformer. The sound of a cooling fan cannot be heard. Some welding fans are turned on only when some machines need to be cooled. If you do not hear anything, you must check the circuit that supplies power to the machine and the fuse box switches. Welding machines require a large amount of electrical power to operate, often at a special installation of 60 amps or more and at 240 volts.

What is ARC welding machine Uses - Steps - Hints - warning.

Hold the electrode holder by the insulated handle with your highly skilled hand, with the rod in a position that allows you to maneuver on the metal so that it can be welded as naturally as possible. Put the welding mask up, just enough to make sure the electrode is a few centimeters away from the piece you are going to weld, ready to bend the mask down and protect your eyes. You will definitely want to follow this movement, and similarly tap the metal with the electrode just to feel the work before turning on the machine, but never create an electric arc in front of your eyes without safety.

What is ARC welding machine Uses - Steps - Hints - warning.

Select the point where you want to start your welding. Place the tip of the electrode near it, then place the mask underneath. At the moment of "hitting" the metal part, the electrical circuit will be completed, then immediately pull the electrode back a little, so that an electric arc is created between the electrode and the welded metal tip. Another way to make an arc is to light a match or matches. The small gap of the arc, or air gap, produces tremendous resistance in the electrical circuit, which is what produces the plasma or arc flame and the heat required for the electrode and metal liquid adjacent to the welding area Is.

What is ARC welding machine Uses - Steps - Hints - warning.

Bring the electrode close to the surface of the metal, gently pull it back when you see the arc occur. This requires a lot of practice, as different diameters of electrodes and amperes will produce arcs at different distances between electrodes and parts, but a permanent arc will occur if you are able to maintain a proper position. In general, the arc space does not exceed the diameter of the electrode. Practice holding the electrode 0.95 mm (3/8 inch) from the piece, then start moving it to the area you want to join by welding. When the electrode is moved, the metal will melt, the molten metal will fill the space and your weld will be formed.

What is ARC welding machine Uses - Steps - Hints - warning.

Practice "passing" over the welding zone with the electrode until you maintain a permanent arc. Keep it at a constant speed and the way you are going to weld it. Once you have mastered the arc control, start joining or welding the welding wire. It is a metal tank that meets two pieces that are welded together. The technique you use to join will depend on the width of the space between the pieces, as it has to be filled, and you want the weld to penetrate. The slower you move the electrode, the deeper the parts will reach welding on the metal. To fill a wide section, the more zigzag or wavy along the tip of the electrode, the wider the width of the welding path.

What is ARC welding machine Uses - Steps - Hints - warning.

Keep the arc stable as you continue the welding. If the electrode sticks to the metal, pull the rod from the clamp or welded metal to release it. If the arc is lost because you have placed the electrode too far away from the metal surface, stop the process and clean the slag from the place where you are welding to continue the preparation of the arc, so There will be no substances that will contaminate your wire or path. Welding from the point where you lost the arc. Never leave dirt where you start welding again as the solder will become bubbly, weak and dirty.

What is ARC welding machine Uses - Steps - Hints - warning.

Practice moving the electrode with a wide zigzag movement to form a wide weld. This will allow you to fill more solders in one pass, leaving cleaner and better welds. The electrode moves from one side to the other as if painting by welding or as if you are making 8 shapes.

What is ARC welding machine Uses - Steps - Hints - warning.

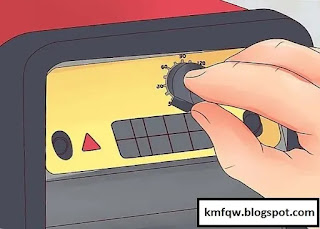

Adjust your welder's output amperage to suit your welding material and desired arc penetration. If you notice that the metal digging around the welding wire, or the surrounding metal, has easily melted or burned, slowly lower the amperage until the situation is corrected. If, on the other hand, you have difficulty building or maintaining an arch, you may need to increase the amperage.

What is ARC welding machine Uses - Steps - Hints - warning.

Clean your finished welding. After finishing welding, you will definitely want to remove this slag and clean your weld, perhaps because the paint will grip better or look better. File the surface and brush with a wire brush to remove any of the material. If the surface has to be flat so that the piece fits with another one you are going to weld, use a grinder to remove the top, or the part that comes out of the weld. A clean weld, especially after being flattened, is easy to check if it has gone out of bubbles, gaps or any other defect.

What is ARC welding machine Uses - Steps - Hints - warning.

Paint your welding with a suitable material to prevent oxidation and corrosion. The new welded area can oxidize faster than other parts of the part, especially if it is exposed to moisture.

- Hints

- Some experts "hear" the sounds produced by the electric arc to test the quality of the weld. Small bursts or clicks may indicate the location of the opposite arc or the improper imperial.

- When you cut very long pieces together and it is difficult to pinch them, keep small solder points with them so that they are temporarily held during welding. This will save them from being separated during the process

- Things you will need

- The metal stays warm for a long time after welding, so keep pets and children away from the work area until the material has cooled.

- Soldiers should avoid breathing in the smoke created during the process. This applies especially to galvanized or silver materials, and also to metals that have been painted with a metal oxide primer.

- Welding machines use very high amperage, which is extremely dangerous, so handle cables and clamps very carefully. Never weld in rain or wet material without proper training.

- Periodically inspect cables and connections to minimize power outages.

- Cover your skin with gloves, masks and long sleeves to prevent burns. Never weld without a helmet type mask.

- Bright light from an electric arc can cause sun-like burns, so wear a long-sleeved shirt and long pants to reduce skin exposure.

- Things you will need

- Welding machine with wires, clamps and electrodes

- Preparation and cleaning of welds, including hammer, wire brush and angle grinder

- Safety devices

Also Read About this Link:

0 Comments